User:Mzahm: Difference between revisions

| Line 15: | Line 15: | ||

This apparatus is used to apply metal or ceramic coatings to surfaces. The device functions as follows: | This apparatus is used to apply metal or ceramic coatings to surfaces. The device functions as follows: | ||

An electric arc is created [37], emanating from the cathode electrode [32]. Gas is pumped from the gas supply tube [26] into the annular chamber [41], surrounding the cathode electrode [32] and flowing out of the exit nozzle [34a]. The conical reduction section [35] helps to create a vortex flow for the gas, giving it a higher velocity as it exits the nozzle [34a]. The interaction between the gas and the arc ionizes the gas, creating the plasma, and this plasma atomizes the powder entering the nozzle [27'] and deposits it on the surface of the workpiece via the plasma flame jet [38], creating the surface coating. | An electric arc is created [37], emanating from the cathode electrode [32]. Gas is pumped from the gas supply tube [26] into the annular chamber [41], surrounding the cathode electrode [32] and flowing out of the exit nozzle [34 & 34a]. The conical reduction section [35] helps to create a vortex flow for the gas, giving it a higher velocity as it exits the nozzle [34a]. The interaction between the gas and the arc ionizes the gas, creating the plasma, and this plasma atomizes the powder entering the nozzle [27 & 27'] and deposits it on the surface of the workpiece via the plasma flame jet [38], creating the surface coating. | ||

Revision as of 21:20, 21 January 2011

Patent 4788402: HIGH POWER EXTENDED ARC PLASMA SPRAY METHOD AND APPARATUS

Patent Date: November 29, 1988

Inventor: James A. Browning

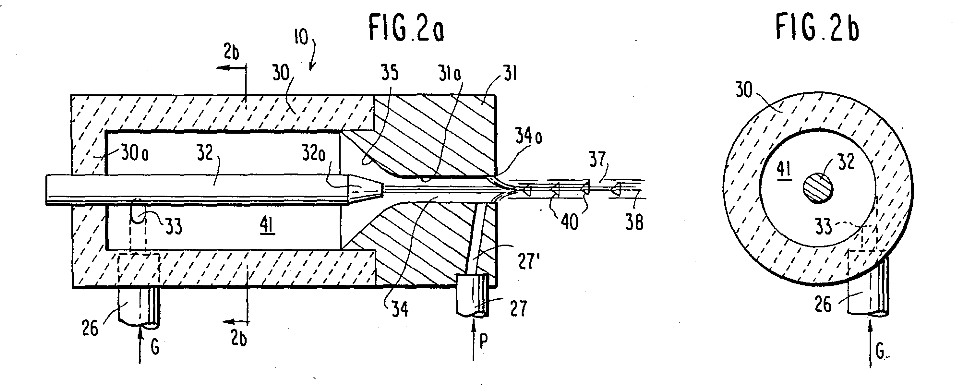

Figure 2a shows a longitudinal view of the apparatus, while Figure 2b shows a cross-sectional view taken about the line 2b-2b.

Basic Description:

This apparatus is used to apply metal or ceramic coatings to surfaces. The device functions as follows:

An electric arc is created [37], emanating from the cathode electrode [32]. Gas is pumped from the gas supply tube [26] into the annular chamber [41], surrounding the cathode electrode [32] and flowing out of the exit nozzle [34 & 34a]. The conical reduction section [35] helps to create a vortex flow for the gas, giving it a higher velocity as it exits the nozzle [34a]. The interaction between the gas and the arc ionizes the gas, creating the plasma, and this plasma atomizes the powder entering the nozzle [27 & 27'] and deposits it on the surface of the workpiece via the plasma flame jet [38], creating the surface coating.